This engine is the result of our effort to solve a request to create new lightweight, powerful and low vibration unit for an ultralight airplanes. The main request was high power/weight ration and low vibration.

Evolution of Birotary engine: Our Invention History

The Birth of The Idea

Jan, 1988: nventor and designer Vaclav Knob starts working on the Birotary Engine idea development.

Established of Knob Engines Ltd.

Jun, 2010: Mr. Václav Knob, based on previous research and review of patents for rotary and bi-rotary engines, is establishing the company Knob Engines Ltd. with the aim to develop and patent-protect a new and more efficient concept of a bi-rotary combustion engine.

Filing of Patent Applications

Jun, 2012: Mr. Václav Knob is submitting the first patent applications for the protection of his devised solution of a bi-rotary engine.

CZ Patent CZ304371

Feb, 2014: Gathered first CZ Patent CZ304371

US Patent

Dec, 2014: Granted the US Patents US9366200 – Engine Sealing and US9322274 – Bi-rotary Engine Concept. Additional patents and international application are pending.

Investor Entry

Jul, 2015: After years of dedication, planning, and preparatory efforts in the project to manufacture a functional prototype, an investor has been successfully found.

First Engine Start

Feb, 2016: After several unsuccessful attempts and overcoming the initial teething problems of this unique design, the bi-rotary engine was successfully started and operated at the test bench located in the VTP Roztoky.

Another Patents Gathered

Jan, 2017: Patents received in Canada, EU, Australia, South Africa, Japan, China and Eurasia…

Completion of the Functional Prototype

Jul, 2019: In 2019, another milestone in the development was reached when we managed to refine and enhance the functional prototype of the engine to the extent that it is capable of starting without the assistance of a dynamometer.

Start of the Hybrid Drive Project

Jan, 2020: In 2020, following the successful ongoing development of the bi-rotary engine, a project for the development of hybrid propulsion for ultralight aircraft was obtained.

Successful Completion of the Hybrid Drive Project

Apr, 2023: Successful completion of hybrid propulsion projects. The bi-rotary engine has achieved nearly computational performance parameters.

Continuation of Development

May, 2023: Because the management of Knob Engines did not present any continuation of development and Vaclav Knob as a minority owner is not able to change this situation, he decided to continue the development on his own.

New Patent Granted

Oct, 2023: New patents have been granted for improvements to the sealing of the bi-rotary engine. These patents are the exclusive property of Mr. Vaclav Knob.

Preparations for Further Development…

Jan, 2024: This year, preparations are underway for the further development of the bi-rotary engine, and the search for financial resources for the continued development.

Challenges of Birotary Engine Design

Throughout the history of combustion engine development, the ongoing desire to create a more capable rotary internal combustion engine has inspired various designs, generated many technological innovations and provided important learnings for engine manufacturers across the years. The constant demand driven challenge to produce ever increasingly smaller engines while delivering increased specific power output provides ongoing stimulation and opportunity for new concepts with improved designs. The successful development of a further improved high quality rotary engine has significant commercial potential in the field of lightweight aircrafts, unmanned aerial vehicles, marine applications and currently also in the field of hybrid engine solutions. In these fields, a new improved engine development with comparative advantages can provide notable and visible benefits. These benefits comprise compact dimensions, lightness, Noise Vibration Harshness (NVH) parameters and simplicity of design. An improved rotary engine, for example, would be able to make hybrid vehicles cheaper, less complex, lighter, more spacious and more powerful than they are today. This is clearly evidenced by review of several recently published car manufacturers hybrid concepts (AUDI, MAZDA, etc.).

Historical Rotary Engine Designs

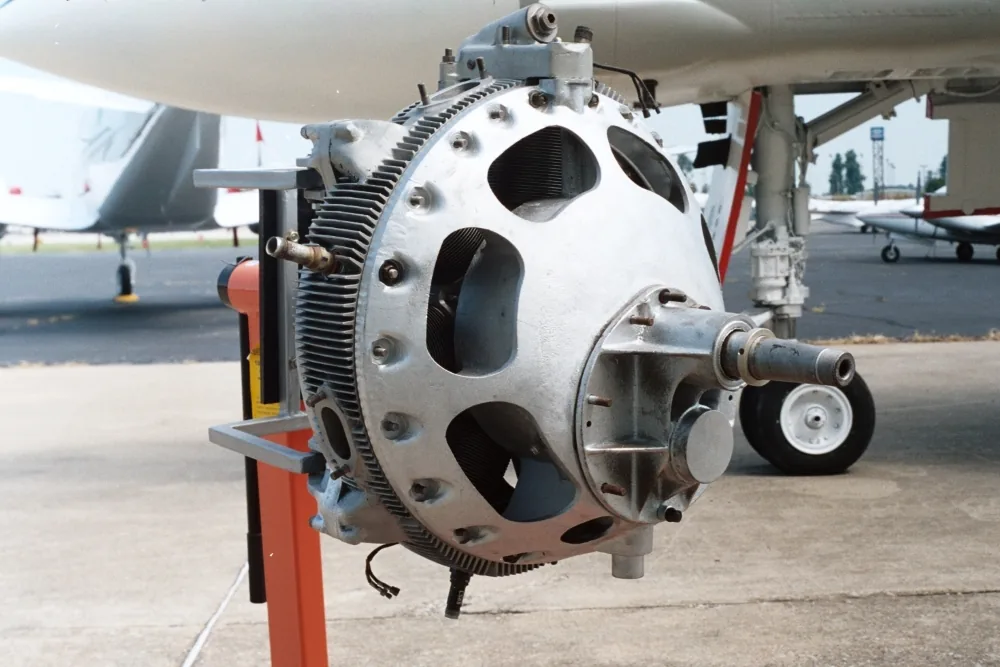

Piston rotary aircraft engines have a long history dating back to early 1900s. Their concept was based on rotating their cylinder block around a static crankshaft. The engines had a valvetrain with poppet valves, which rotated with the cylinder block. While these engines enjoyed a considerable success in WWI, issues such as significant air resistance losses, the gyroscopic effect from the large rotating masses and total loss lubrication system led to their demise.

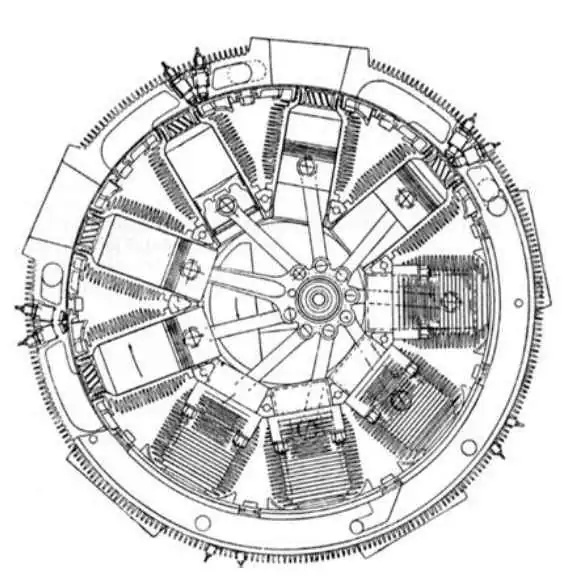

The Birotary concept was introduced in a 1914 patent of Ignacz Sklenar see figure below. His engine used a rotating cylinder block also as a slide valvetrain. The crankshaft rotated in the opposite direction to the cylinder bloc to reduce gyroscopic effects. However, engines based on Sklenar’s concept were large, multicylinder engines with large piston stroke and air cooling. Their design did not offer significant advantages versus traditional piston engines of their times.

Knob Birotary Engine Concept

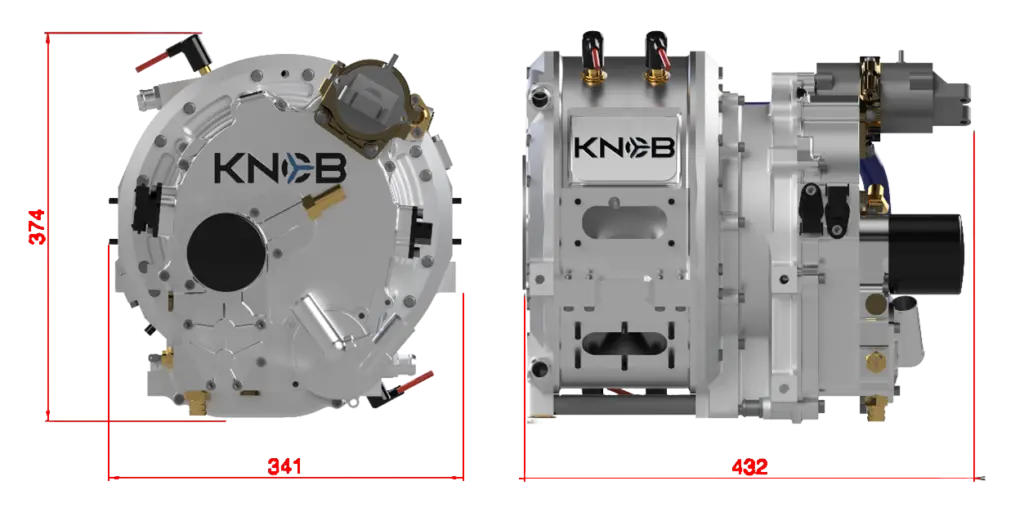

Mr. Vaclav Knob started its development with a goal to create a reliable and powerful rotary piston engine. To do so, his engine concept brings significant changes to Sklenar’s concept:

- Only three cylinder block, with cylinders arranged in a “star” at 120-degree angles; 6, 9 or 12-

cylinder version can be produced by extending the engine in the axial dimension - Very short stroke and large bore to reduce engine’s dimensions and increase the maximum RPMs

- Innovative combustion chamber sealing, which is patented

- Water and oil cooling: oil cools the cylinder block and pistons and water cools the cylinder head. In

the future, an oil-only cooling system can further reduce the number of engine accessories required.