The First Test

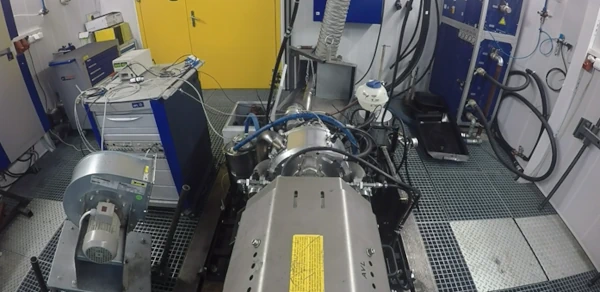

The first tests of the prototype were done at the modern CTU research center in Roztoky near Prague in early 2016. The development team was involved in the tests, in cooperation with the test cell engineers of the Centre of Vehicles for Sustainable Mobility based at the Czech Technical University. Engine test cell with DAQ system was used to obtain information about engine behavior under load conditions.

During the tests was used 5800 RPM (relative engine speed). The engine was run at low throttle setting. These tests were not intended to test the maximal power output curve of the engine. The first prototype tested was not designed for high power output.

These first tests provided engineers the opportunity to monitor the performance and functionality of the individual engine parts and identify potential improvement opportunities. Several minor issues were identified such as partial oil leakage into the fuel mixture. Some of these issues were resolved immediately on site while others required minor construction adaptations to the prototype.

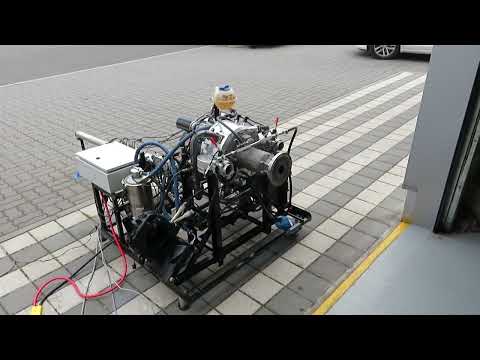

Video of the First time start

Videos of engine testing